Discharging and metering valve for powders

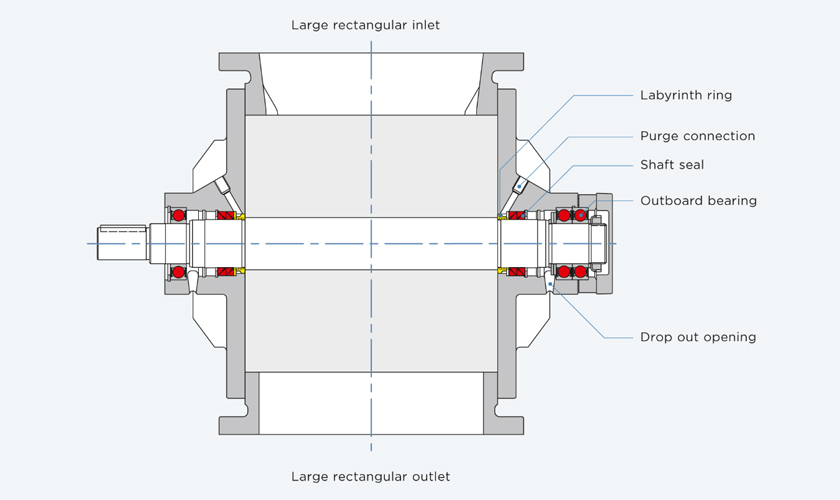

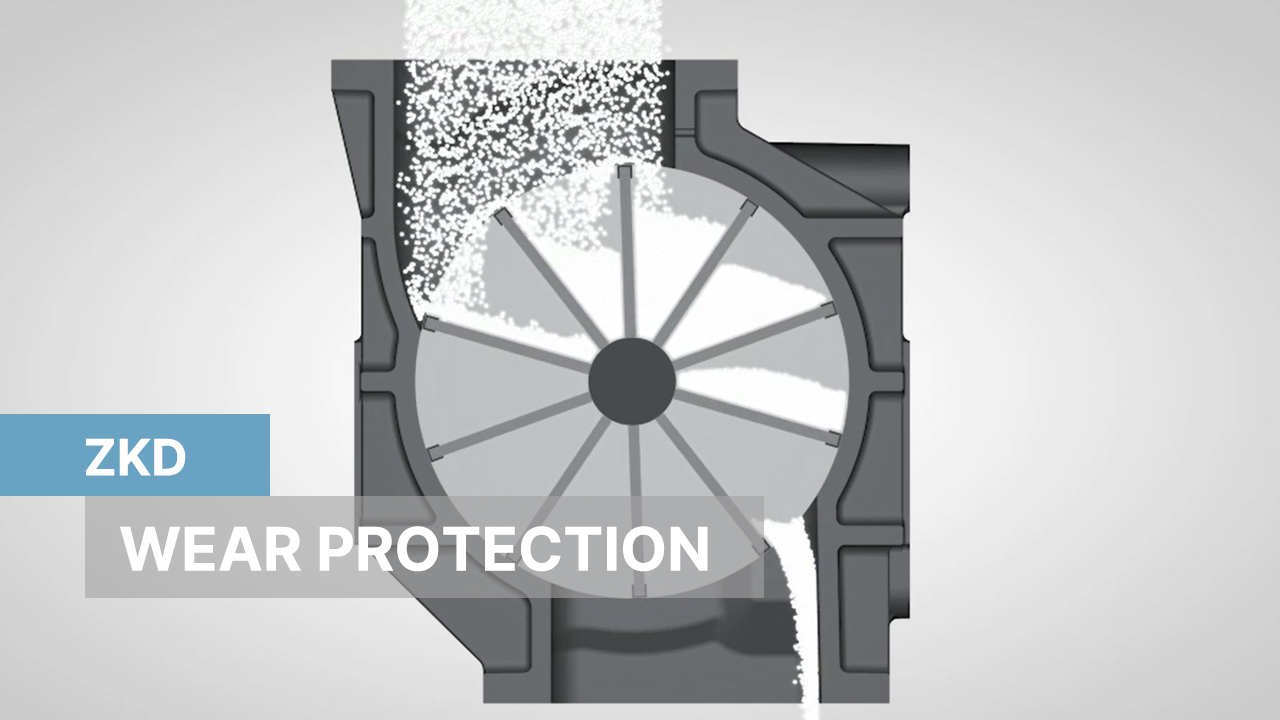

The ZKD rotary valve is designed with a robust solid housing that includes rectangular flange connections, ensuring durability and stability in demanding applications. This construction not only enhances the valve's longevity but also facilitates easy installation and integration into existing systems. Additionally, the ZKD is equipped with a feeding shoe, making it highly versatile for efficiently feeding bulk materials into pneumatic conveying systems at pressures of up to 1.5 barg (21 psi). It is suitable for a wide range of industries, including plastics, chemicals, food, and minerals, providing reliable performance and seamless operation tailored to meet the specific needs of modern industrial processes.