Innovative wear protection concepts for maximum economy

There are many reasons, why Coperion is the ideal partner for the minerals industry

- We have experience with more than 15,000 bulk materials

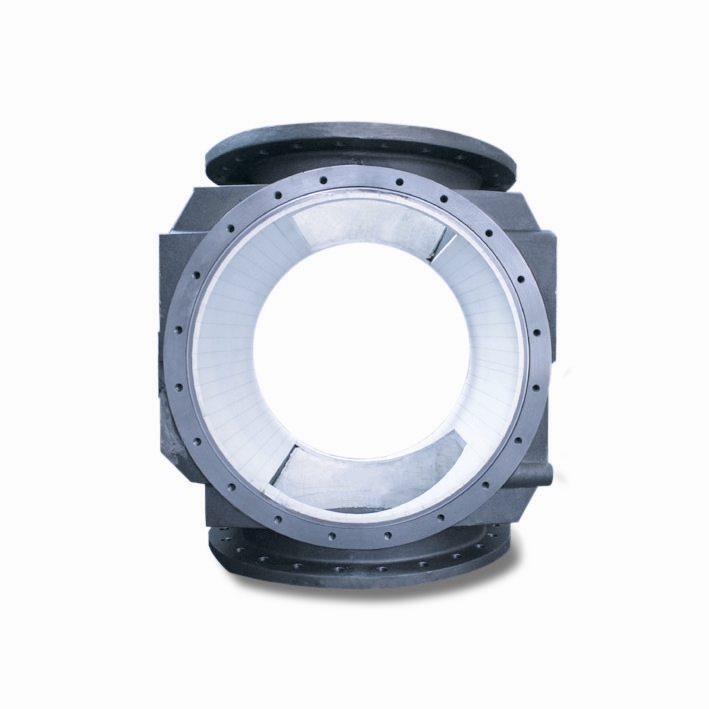

- Coperion components are long-lasting, high-quality products for all applications

- Our DUROPROTECT levels for rotary valves guarantee maximum service life and availability

- In our test center we simulate wear conditions and define the optimum wear protection (DUROPROTECT level).