High-pressure discharging valve for granular products

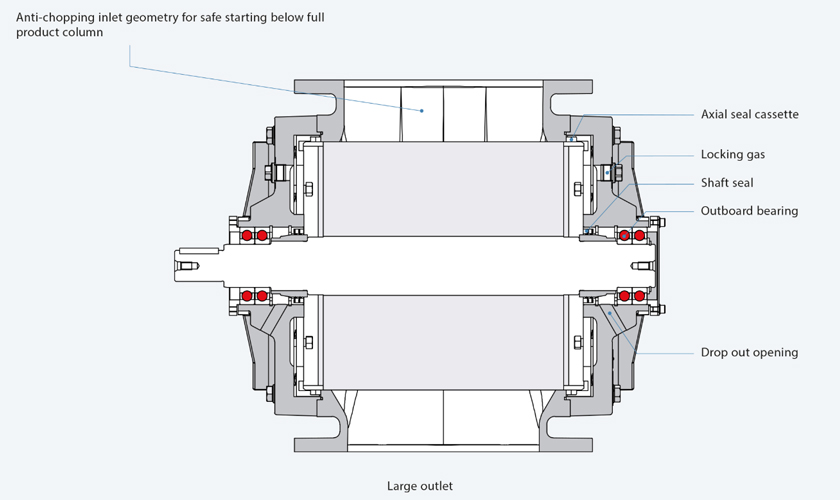

The Rotary Valve ZVH is a high-pressure discharging valve designed specifically for granular products. Engineered to optimize capacity, it features an ideal ratio of rotor volume to inlet cross-section, ensuring efficient material flow. Its unique inlet geometry allows for gentle handling of pellets, minimizing damage and preserving product quality. Additionally, the integrated feeding shoe enhances versatility, making it suitable for feeding bulk materials into pneumatic conveying systems at pressures of up to 3.5 barg (51 psi). Experience enhanced performance and reliability with the Rotary Valve ZVH, tailored to meet your material handling needs.