Discharging Valve for Granular Products

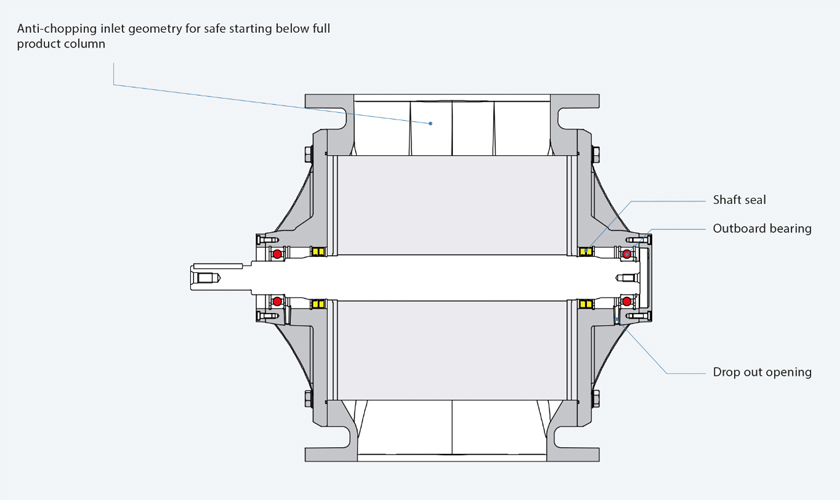

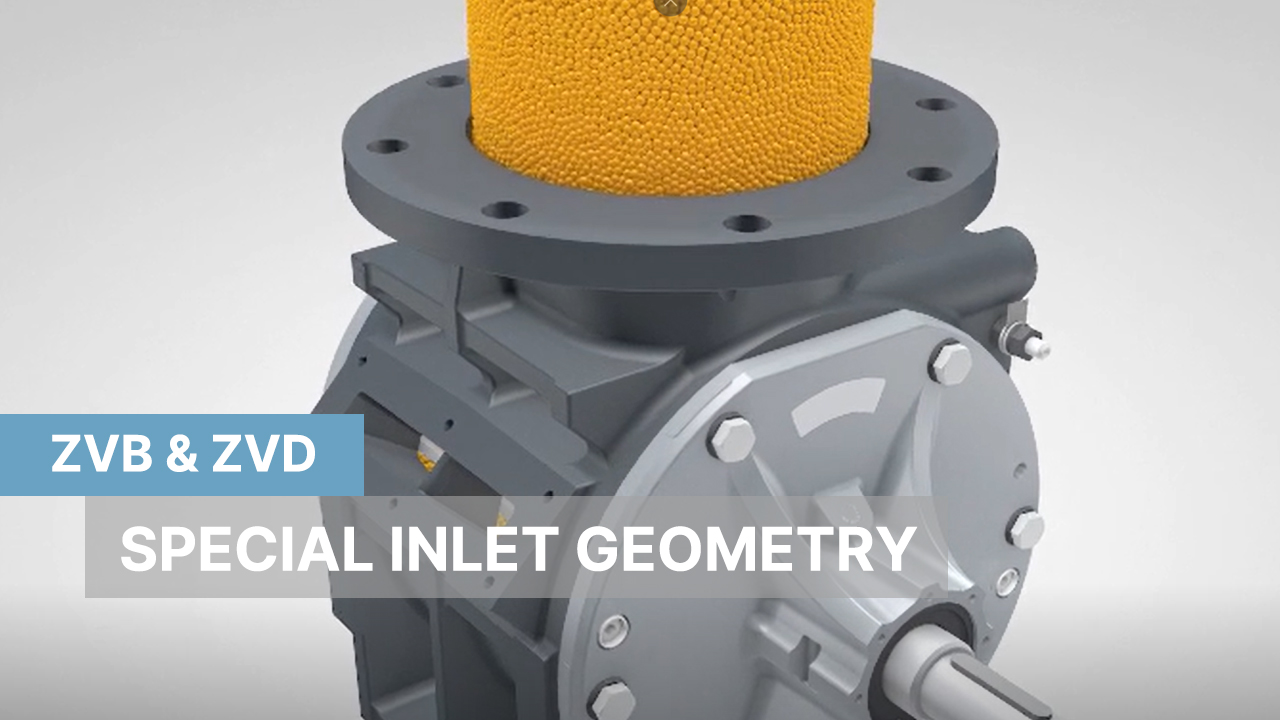

The ZVB is engineered for optimal performance with a maximum capacity achieved through an ideal ratio of rotor volume to inlet cross-section. This innovative design features a specialized inlet geometry that ensures gentle handling of pellets, minimizing damage and maintaining product integrity. Additionally, our rotary valve is equipped with a feeding shoe, making it versatile enough to efficiently feed bulk materials into pneumatic conveying systems, even under pressures of up to 1.5 barg (21 psi). Experience enhanced efficiency and reliability in your material handling processes with our state-of-the-art rotary valve solution.