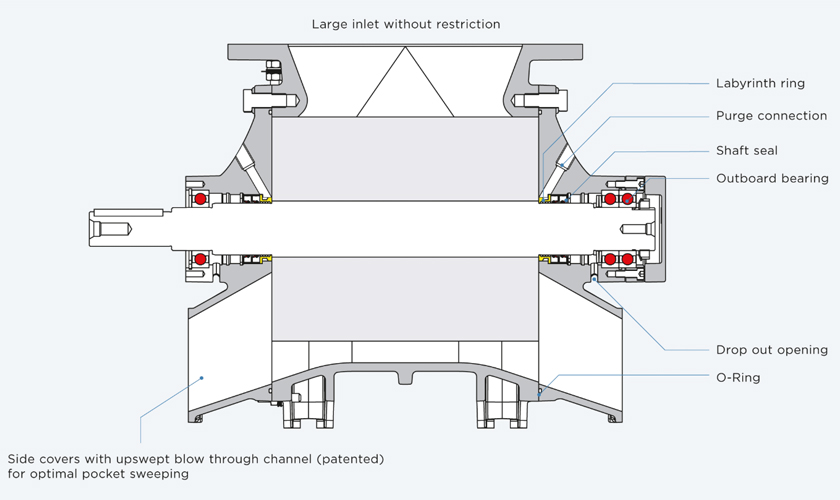

Blow-through valve for powders

The ZXD Rotary Valve is engineered to optimize the feeding of bulk materials into pneumatic conveying systems, boasting a large inlet designed to handle high capacities efficiently. Capable of operating at pressures of up to 1.5 barg (21 psi), this innovative valve ensures reliable performance in demanding industrial applications. Notably, the ZXD Rotary Valve operates without the need for leakage gas venting, effectively enhancing system integrity. This combination of features makes the ZXD Rotary Valve an essential component for industries requiring efficient and reliable bulk material handling solutions.