Discharging Valve For Fine And Coarse-grained Products

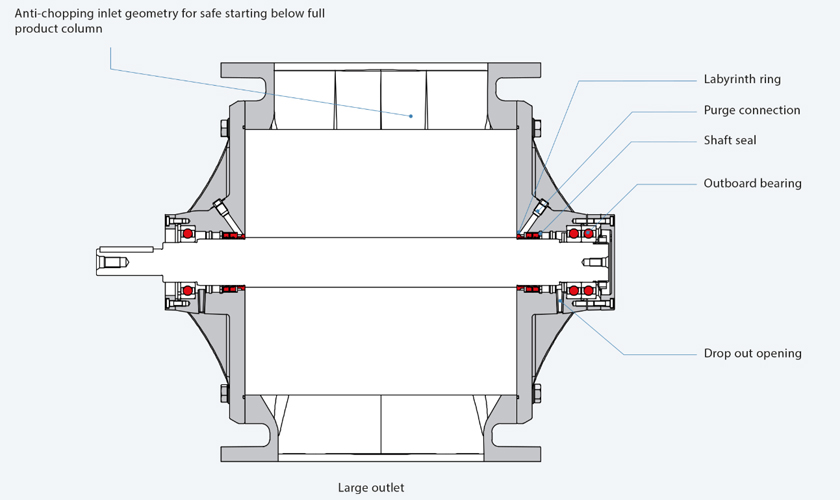

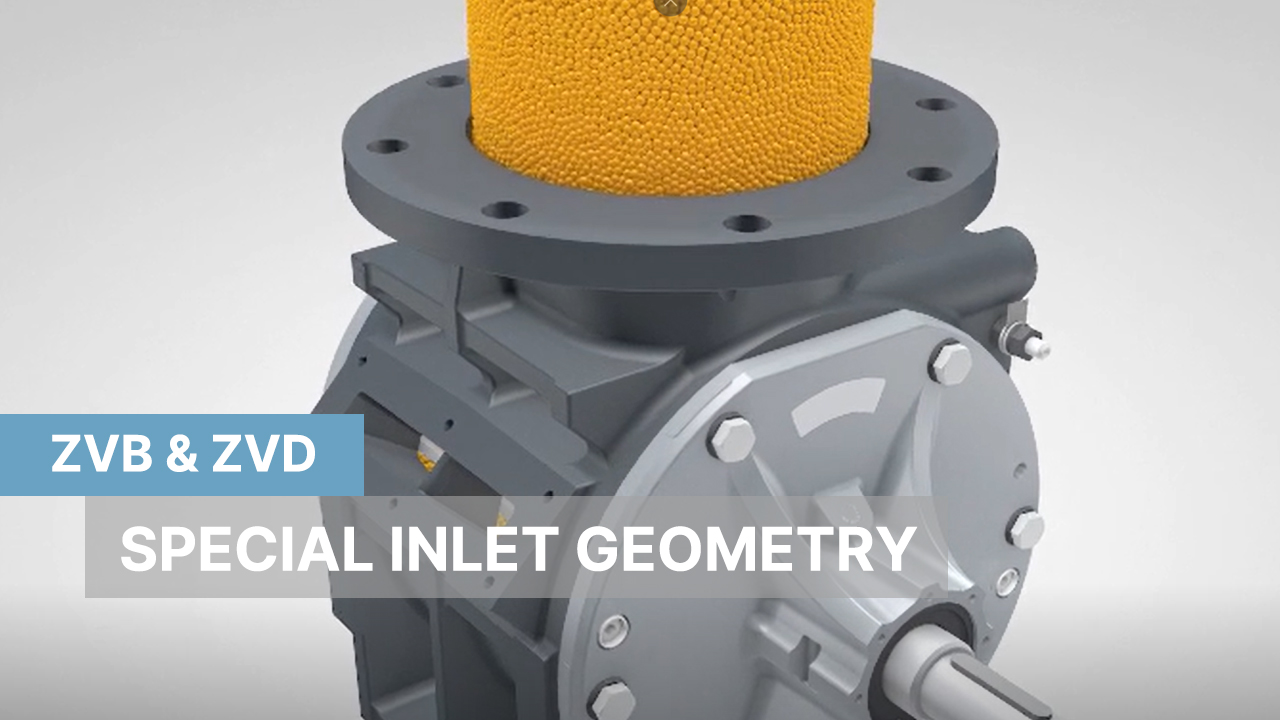

The ZVD is engineered for maximum capacity, achieved through an optimal ratio of rotor volume to inlet cross-section. This design ensures efficient material flow while maintaining high performance standards. The valve incorporates a specially designed inlet geometry that is purpose-built for gentle product handling, minimizing the risk of damage to sensitive materials during transfer. Additionally, the integrated feeding shoe enhances versatility, allowing the valve to effectively feed bulk materials into pneumatic conveying systems at pressures of up to 1.5 barg (21 psi). Experience unparalleled efficiency and reliability in your material handling processes with our innovative rotary valve solution.