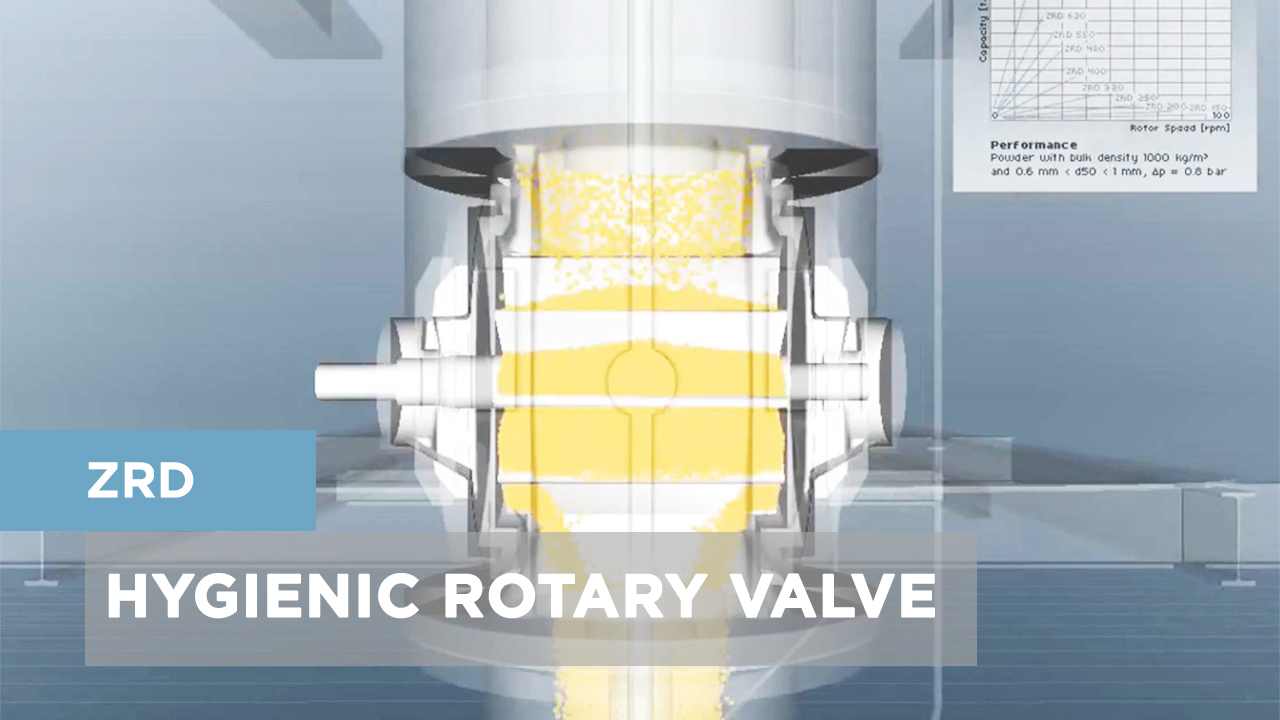

Discharging and Metering Valve for Powders

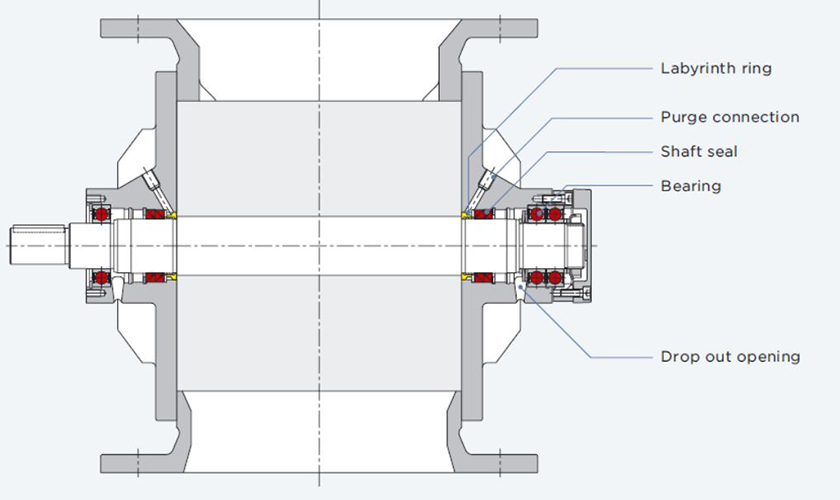

Coperion's ZRD Rotary Valve is engineered for versatility and efficiency across various industrial applications. Its unique bucket box principle features a large inlet geometry, allowing for optimal material flow. The valve boasts a premium sealing system with double shaft seals and a labyrinth ring for effective gas purging, ensuring maximum reliability. Designed with user convenience in mind, the ZRD includes outboard bearings and a separate drop-out opening for easy detection of gasket failures. With customizable rotor options (a 10-chamber open-end D-Rotor for powders, an X-Rotor for fibrous materials, and a C-Rotor for abrasive products) the ZRD Rotary Valve is the perfect solution for your processing challenges.